More Information on Enforcement Actions Against U.S. Steel (Clairton)

The U.S. Environmental Protection Agency and the Allegheny County Health Department have taken several enforcement actions against U.S. Steel relating to air emissions from its Clairton coke plant, resulting in Consent Orders. They contain some provisions that reflect the types of structural changes needed to generate significant reductions in air emissions.

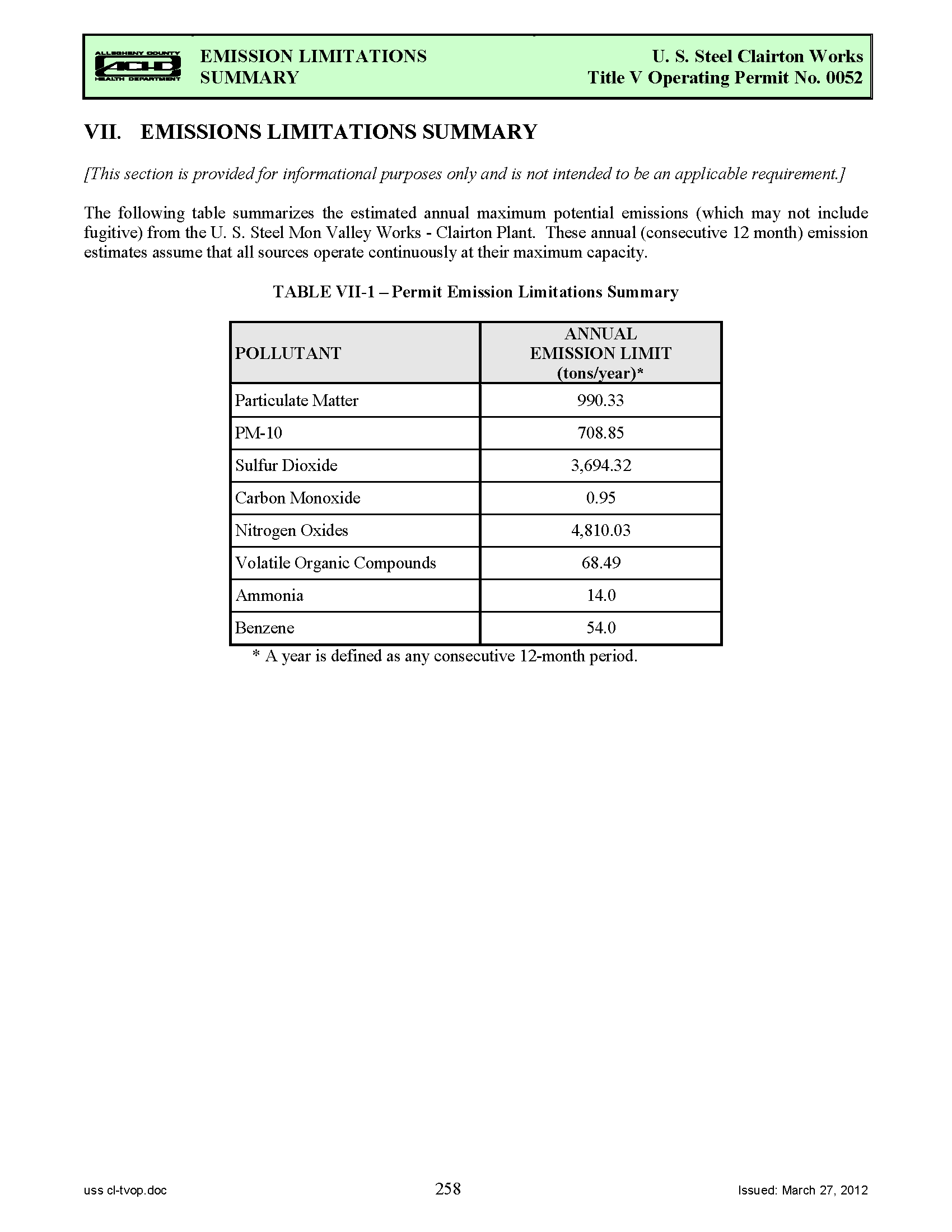

1. Significant emissions from the facility:

| Pollutant | Annual Emissions Limit (tons/year, based on any consecutive 5-year period) |

| Particulate Matter | 990.33 |

| PM-10 | 708.85 |

| Sulfur Dioxide | 3,694.32 |

| Carbon Monoxide | 0.95 |

| Nitrogen Oxides | 4,810.03 |

| Volatile Organic Compounds | 68.49 |

| Ammonia | 14.0 |

| Benzene | 54.0

|

Title V Permit (full):

Title V Permit (Emissions Limitations Summary):

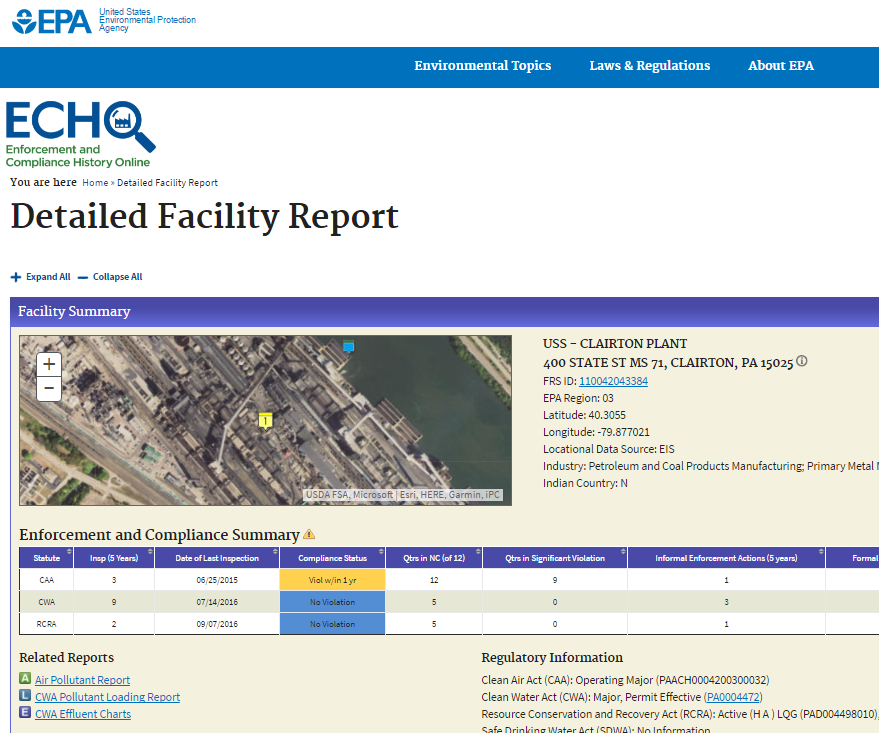

2. EPA Webpage on Enforcement Activity for the Clairton Facility.

According to EPA, the facility has been in noncompliance with the Clean Air Act for all 12 of the last 12 quarters. There have been one informal enforcement action and 21 formal enforcement actions during the last 5 years.

Source: EPA’s Compliance and Enforcement History Online (ECHO), for the Clairton facility:

3. Consent Order and Agreement, March 17, 2008

The Allegheny County Health Department and U.S. Steel entered into a consent order that required a number of corrective actions.

The Consent Order addressed a series of 67 instances where pushing emissions exceeded 20 percent capacity, and one instance where visible emissions from the transport of coke in the open atmosphere exceeded 10 percent opacity.

Summary of Terms and Conditions:

A. Batteries 7, 8, and 9

- Advanced Patching Plan, https://pacokeovens.org/wp-content/uploads/2016/08/appx-A-Advanced-Patching-Plan-17-Mar-2008-USS-ACHD-consent-agreement.pdf

- Regenerator Repair Plan, https://pacokeovens.org/wp-content/uploads/2016/08/appx-C-Regenerator-Repair-Plan-17-Mar-2008-USS-ACHD-consent-agreement.pdf

- Gas Gun Improvement Plan, https://pacokeovens.org/wp-content/uploads/2016/08/appx-D-Gas-Gun-Improvement-Plan-17-Mar-2008-USS-ACHD-consent-agreement.pdf

- Shut down batteries by December 31, 2012

B. Batteries 1, 2, and 3

- Advanced Patching Plan

- Flue Nozzle Repair Plan, https://pacokeovens.org/wp-content/uploads/2016/08/appx-B-Flue-Nozzle-Repair-and-Replacement-Plan-17-Mar-2008-USS-ACHD-consent-agreement.pdf

- Regenerator Repair Plan

- Gas Gun Improvement Plan

- Complete automation of reversing rooms by July 31, 2008

- Shut down batteries by December 31, 2014

C. Battery 15

- Complete a second and third round of Enhanced Preventive Maintenance Refractory Repair Plan, https://pacokeovens.org/wp-content/uploads/2016/08/appx-E-Enhanced-Preventive-Maintenance-Refractory-Repair-Plan-17-Mar-2008-USS-ACHD-consent-agreement.pdf

- Achieve compliance with opacity standards by December 31, 2008

D. Battery 19

- Replace 25 heating walls

- Achieve compliance with opacity standards

- Advanced Patching Plan

E. Battery 20

- Completely install WOBBE stabilizer

- Replace 88 heating walls

- Achieve compliance with opacity standards

- Advanced Patching Plan

- Revitalization Plan of Battery Heating System

F. Number 3 Screening Station

- Submit application for installation permit for new baghouse, as well as Compliance Plan

4. Consent Order and Agreement, August 7, 2014

The Allegheny County Health Department and U.S. Steel entered into a consent order that required a number of corrective actions.

This addressed a series of instances where charging emissions from Battery C exceeded standards for visible emissions. The facility installed this battery and started up operations in this battery on or about November 24, 2012.

Battery C includes 84 ovens with charging ports, doors, lids, and offtakes, a Quench Tower, a Pushing Emissions Control System, and an Underfire Combustion Stack.

The Department filed a Complaint and a Consent Order on the same day:

Summary of terms and conditions:

A. Charging Visible Emissions for C Battery

- operate baffle wash system or equivalent system of the B Quench Tower during quenching of coke, as long as ambient temperature is above 32 degrees Fahrenheit

- complete the engineering, design, and installation of C Battery U-Tube system

- certify compliance with charging standards, or provide an updated Compliance Schedule if it is unable to certify compliance

- shut down batteries by December 31, 2012

B. PEC Baghouse, Low Emissions Quench Tower, Underfire Combustion Stack

- submit request for permit modification to address alleged violations of permit for emissions from these units

5. PennFuture’s Notice of Intent to Sue, January 28, 2016

Citizens for Pennsylvania’s Future (PennFuture), a non-profit environmental organization filed a Notice of Intent to Sue with the Allegheny County Health Department on January 28, 2016.

The organization alleged numerous violations of the federal Clean Air Act, the Pennsylvania Air Pollution Control Act, and the Department’s rules and regulations.

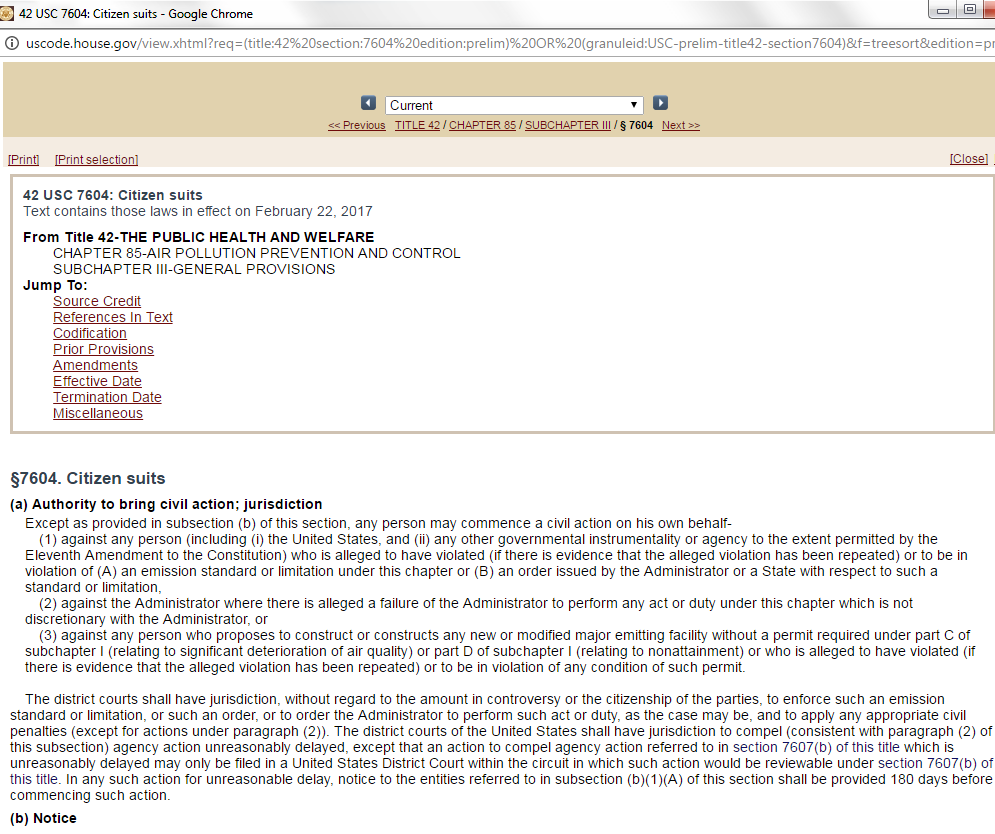

Under the Clean Air Act, PennFuture was required to provide 60 days’ notice of intent to sue, before commencing a citizen suit action in federal court. 42 U.S.C. § 7604(b)(1)(A).

For Batteries 1, 2, 3, 13, 14, 15, 19, 20, and Battery B, PennFuture alleged numerous violations of the 20% opacity standard (Art. XXI, Section 2105.21.f.3) and the 60% opacity standard (Section 2105.21.f.4).

For the Pushing Emission Control (PEC) Systems for these batteries, PennFuture alleged numerous violations of the 20% opacity standard (Section 2105.21.e.4), the Reduced Efficiency Pushing Standard (Section 2105.03), and the Continuous Operation Standard (Section 2105.03).

PennFuture alleged the facility violated applicable emissions limitations on approximately 6,700 occasions.

6. Consent Order and Agreement, March 24, 2016

56 days after receive the Notice of Intent to Sue, the Department filed a complaint with the Court of Common Pleas in Allegheny County:

The Complaint consists of fifteen (15) counts, includes those intending to address PennFuture’s allegations:

| Count | Violation | Section |

| I | 20% opacity limitation for combustion stacks | 2105.21.f.3 |

| II | 60% opacity limitation for combustion stacks | 2105.21.f.4 |

| III | 10% opacity limit for travel emissions | 2105.21.e.5 |

| IV | 20% opacity limit for pushing emission control devices | 2105.21.e.4 |

| V | reduced efficiency pushing | 2105.03 |

| VI | continuous operation standard | 2105.03 |

| VII | failure to perform emissions testing of C Battery underfire | 2101.11 |

| VIII | exceedence of emission limits for sulfur dioxide, carbon disulfide, and total reduced sulfur from C Battery quench tower | 2101.11 |

| IX | exceedence of emission limits for total reduced sulfur and carbon disulfide from C Battery PEC System | 2101.11 |

| X | coke battery offtake piping — visible emissions percentage | 2105.21.d.1 and d.2 |

| XI | coke battery charging ports (lids) — visible emissions percentage | 2105.21.c.1 and c.2 |

| XII | coke battery aggregate charging | 2105.21.a.1 and a.2 |

| XIII | coke battery doors — visible emissions percentage | 2105.21.b.1 and b.2 |

| XIV | coke battery 40% doors | 2105.21.d.1 and d.2 |

| XV | soaking | 2105.21(i) |

On the same date, the Department filed a Consent Judgment signed by the Department and the company, and approved by the Court.

The requirements in this consent order supersede the 2011 and 2014 consent orders and agreements.

The following is a summary of the Compliance Requirements:

1. Oven Wall Inspections (Batteries 2, 3, and 15)

a. Conduct an inspection of the oven walls and submit an Oven Wall Study to the Department.

b. If repairs or upgrades are necessary, submit an Oven Wall Study Work Plan and implement it as expeditiously as possible.

2. Certification of Compliance with Performance Standard (Batteries 2, 3, and 15)

a. Within three years, certify that for two consecutive quarters, the battery emissions comply with the 20% and 60% opacity limitations, for at least 98.5% of the reported hourly measurements, and that there is not a systematic component failure causing exceedences.

b. If these requirements are not met, then stipulated penalties will be triggered.

c. If the Oven Wall Study Work Plan demonstrates that refractory replacement at a battery is necessary, and a good faith engineering estimate is at least $15,000,000, the facility may submit to the Department a new deadline to meet the requirements and obtain the compliance certification.

3. Continuing Obligations for Batteries 1, 2, and 3

a. Soaking emissions are defined as uncombusted emissions from an open standpipe which has been dampered off in preparation of pushing the coke mass out of the oven, and end when pushing begins when the coke side door is removed.

b. At no time may the soaking emissions from the standpipe cap opening exceed 20% capacity. An exclusion from this opacity limit is allowed for two minutes after the standpipe is opened.

c. The coking time shall not be less than 21.75 hours, for each of the three batteries. The facility is required to submit to the Department information on deviations from this requirement, on a quarterly basis. Coking times less than this time period are considered to be in compliance if they are caused by or are related to a Start-Up, Shutdown, Breakdown, or Malfunction, or if they are caused by extraordinary circumstances.

d. The facility can propose a compliance demonstration for a shorter coking time, if it determines that compliance can be maintained at a shorter coking time.

e. The facility must maintain records of coking times for five years from the date of each push, and they are treated as Confidential Business Information.

f. Each day, the facility must perform 4 soaking observations for each of the three batteries.

g. Each day, the facility must observe at least 8 pushes for each of the three batteries, at least 4 of them being consecutive.

h. Before meeting the compliance certification requirements, the facility must implement the Advanced Patching Plan, Flue Nozzle Repair Plan, Regenerator Repair Plan, and Gas Gun Improvement Plan.

4. Continuing Obligations for Battery 15

a. Before meeting the compliance certification requirements, the facility must implement the Advanced Patching Plan.

5. Continuing Obligations for Battery C

a. The facility must operate the baffle wash system of B Quench Tower during the quenching of coke, as long as the ambient temperature is above 32 degrees Fahrenheit.

b. The facility must certify compliance with charging standards or provide an updated Compliance Schedule, by April 30, 2016.

Civil Penalty

The Consent Judgment only imposed an additional civil penalty of $25,000.

While the document memorializes a civil penalty of $3,973,000 in full settlement of all issues and alleged violations, $3,948,000 was already paid in civil penalties under 2008, 2011, 2014 consent orders, and various statements of violation. See Consent Judgment at par. 23, Section VII(A).

Stipulated Penalty

If the facility does not meet or maintain compliance with the compliance certification requirements for any battery, it must pay a stipulated penalty of $20,000 per battery per month. Starting on the thirteenth month of noncompliance, the stipulated penalty rises to $40,000 per battery per month.

Additionally, there is a stipulated penalty of $500 for each clock hour that compliance for the Batteries’ combustion stacks is not achieved for opacity limits. section 2105.21(f)(3) and (f)(4). But the first 33 clock hour opacity limit violations of each battery stack in any calendar quarter shall not be subject to stipulated civil penalties.