Nature and Extent of Air Emissions

Myth: Because of comprehensive regulation at the federal, state, and county levels, there is no significant risk of exposure to air emissions from coke oven facilities.

Reality: Coke oven facilities generate fine particulates, which cause premature mortality, and hazardous air pollutants such as benzene, which cause a number of human diseases. Residents in southwestern Pennsylvania face significantly higher risk of developing cancer and respiratory ailments due to this exposure.

- Residents of Allegheny County have a cancer risk more than twice – and in some cases 20 times – that of those living in surrounding rural areas. [1]

- Pittsburgh ranks as one of the top 10 most polluted cities in the nation today with regard to year-round particle pollution (PM2.5) which increases our risk of heart and lung disease, asthma, adverse birth outcomes, cancer and premature death. [2]

- Studies in Pittsburgh have documented increases in emergency room visits for asthma associated with both ozone and PM2.5 pollution levels.

- In 2015, the prevalence of childhood asthma in Allegheny County was elevated compared to state levels (20% versus 16%).

- According to the Asthma and Allergy Foundation, Pittsburgh ranked as the 4th most challenging place to live with asthma in 2012.

Emission Sources at Coke Ovens

Charging Emissions

Charging emissions are particulate matter (PM) emissions generated from “charging” or transferring coal into the coke ovens. This results in seconds of visible emissions as coal is loaded in stages from the “larry car” and generated gas is pulled from the ovens into the normal gas handling equipment.

Door Emissions

Door emissions occur due to overpressure at the oven during the coking process and gaps and cracks in the surface of an oven’s door. Coke ovens are operated at positive pressure to ensure that air does not enter the coke oven. Air entering the oven will damage the oven and quality of the coke.

Emissions from door leakages are the largest source of fugitive emissions from a coke oven battery and are a significant source of benzene and polycyclic aromatic hydrocarbon (PAH) emissions. Door emissions also may contain PM, CO, SO2, H2S, and NH3.

Charge Lid Emissions

Similar to door emissions, during the coking process gaps and cracks may form in the lids and offtakes located at the top of the coke oven battery. These leaks, while generally smaller than door leaks, result in the emission of the same pollutants as door leaks including benzene, PAH, PM, CO, SO2, H2S, and NH3.

Soaking Emissions

Soaking occurs during the last part of the coking process, usually an hour before the coke is pushed. In this process, byproduct recovery ceases as ovens are taken off of the gas collecting main. Offtakes are then opened and residual gas is vented to the atmosphere. The primary emissions during this are PM, methane, and hydrogen. The severity of these emissions has not been measured, but is estimated based on emission factors derived from pushing.

Pushing Emissions and Green Pushes

Pushing emissions occur when coke is unloaded or “pushed” from the coke oven battery. The majority of these emissions are PM emissions, and are often controlled by mobile scrubber cars, enclosures with gas cleaning devices, or travel hoods. No control is perfect, however, and some fugitive pushing emissions do escape.

Emissions from “green pushes” occur when coke that is not fully coked is pushed. This results in both PM emissions, benzene, and other PAH emissions similar to those found in coke oven gas.

Quenching Emissions

Wet quenching, the process of cooling hot coke, typically produces a large plumes of steam. Within this steam, PM and trace organic compounds can become suspended in the water droplets, resulting in emissions. Panels known as baffles help partially capture these emissions by slowing the flow rate of the steam and capturing some if it on its way up through the quench tower. PM emissions can also be controlled using higher towers (and more baffles), clean water, or through different methods such as dry quenching.

Combustion Stack Emissions

Combustion stack emissions are the result of “underfire burning”, used to produce heat at the coke oven battery necessary for the coking process. At a typical byproduct recovery plant, the main fuel used for combustion is coke oven gas. Burning coke oven gas can result in typical combustion emissions such as PM, NOx, CO, and VOCs. It may also result in SO2 emissions, even after going through desulfurization processes typically found at byproducts facilities, as coke oven gas can potentially be a high-sulfur fuel depending on the coal that is being coked.

Sources

- http://www.heinz.org/UserFiles/Library/PRETA_HAPS.pdf

- http://www.lung.org/assets/documents/healthy-air/state-of-the-air/sota-2016-full.pdf

More Information on the Nature and Extent of Air Emissions

Modes of Operation and Pollution

For more information see “The Coke Oven Manufacturing Sector in the U.S.”

Modern heat recovery coke ovens tend to be less common than byproduct recovery ovens, as heat and energy generated from burning byproducts in the coking process is generally less cost-effective than collecting and selling the byproducts. The number of hazardous air pollutants from heat recovery operations is significantly less than the number of air pollutants from by-products recovery operations. This is due to heat recovery operations burning off volatile organic compounds and hazardous air pollutants, resulting in larger emissions of PM, NOx, and CO, as well as hydrogen chloride (HCl) (aerosols), lead, and mercury. Byproduct recovery facilities tend to emit more volatile organic compounds and hazardous air pollutants due to trying to capture, separate, and sell these chemicals that are VOCs and/or HAPs or generate VOC or HAP emissions.

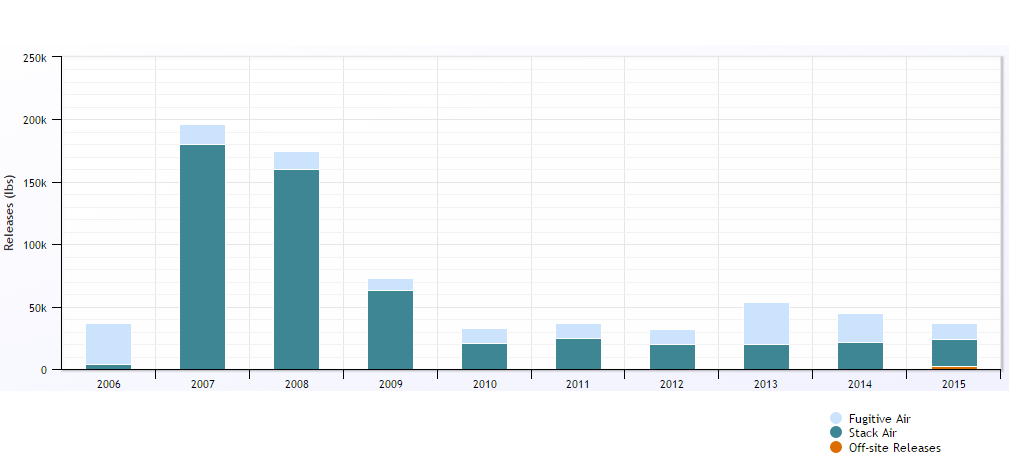

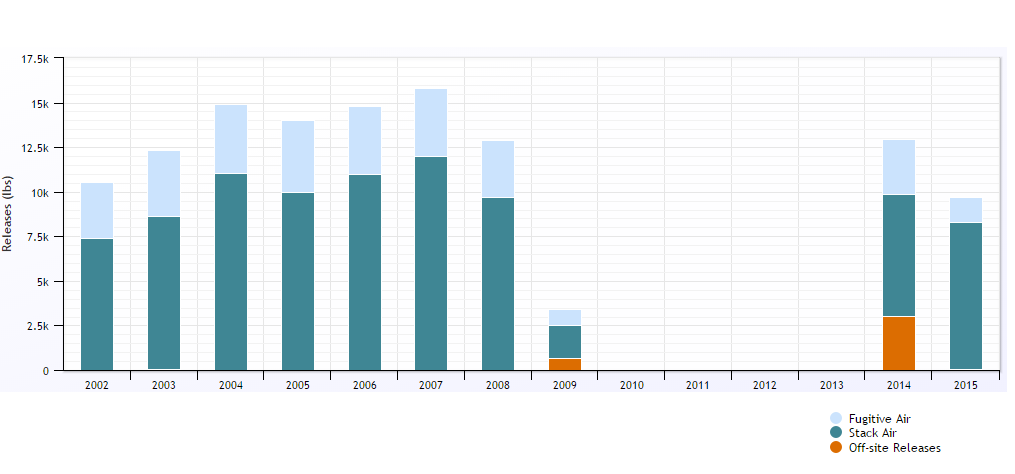

EPA Toxics Release Inventory (TRI)

The EPA Toxics Release Inventory (TRI) keeps track of reported emissions of hazardous air pollutants. All U.S. facilities are required to report releases of these pollutants to EPA once they reach an established threshold determined by EPA. 690 chemicals are currently covered by the TRI program, though it does not include all chemicals hazardous to public health.

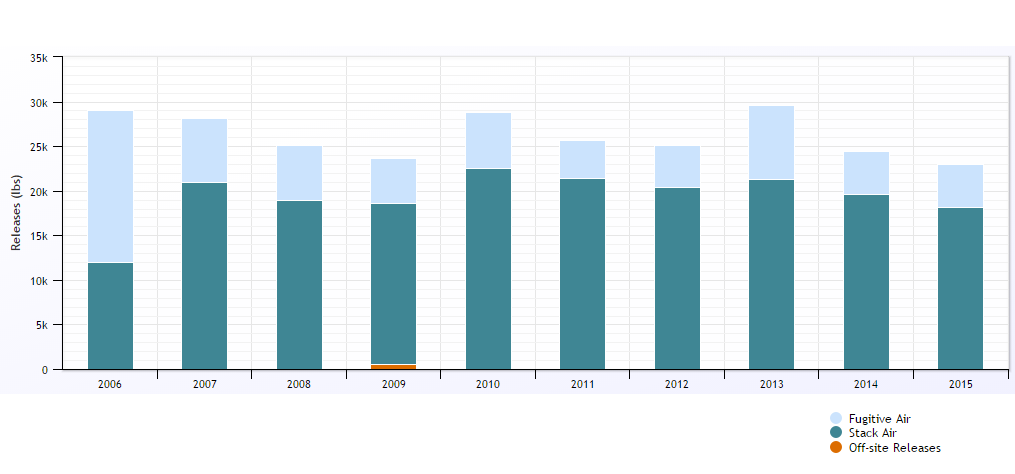

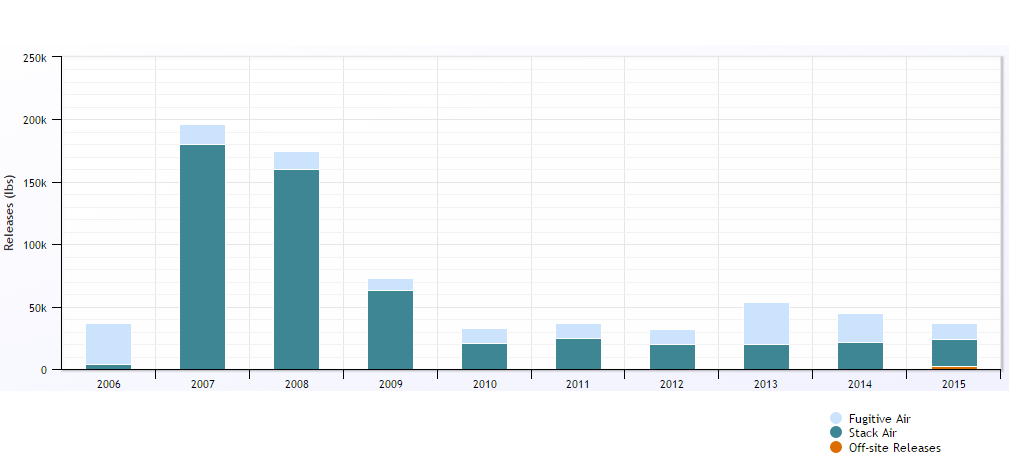

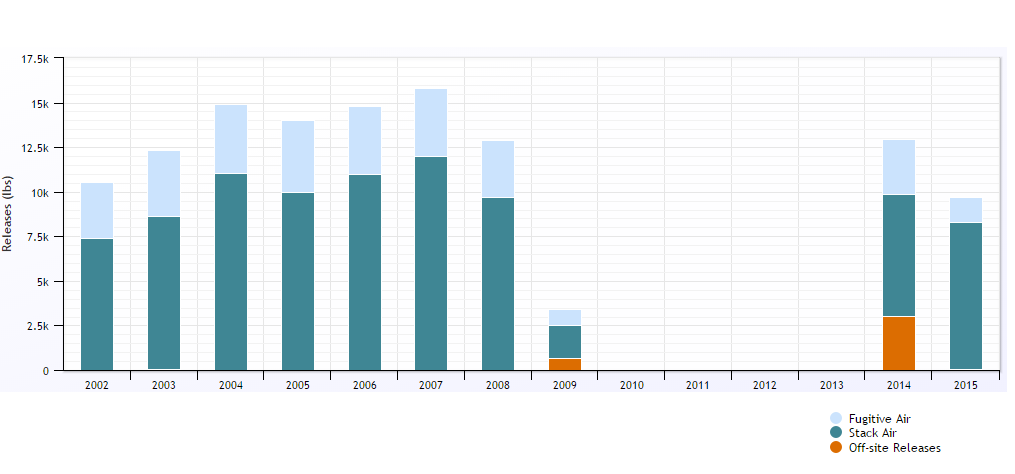

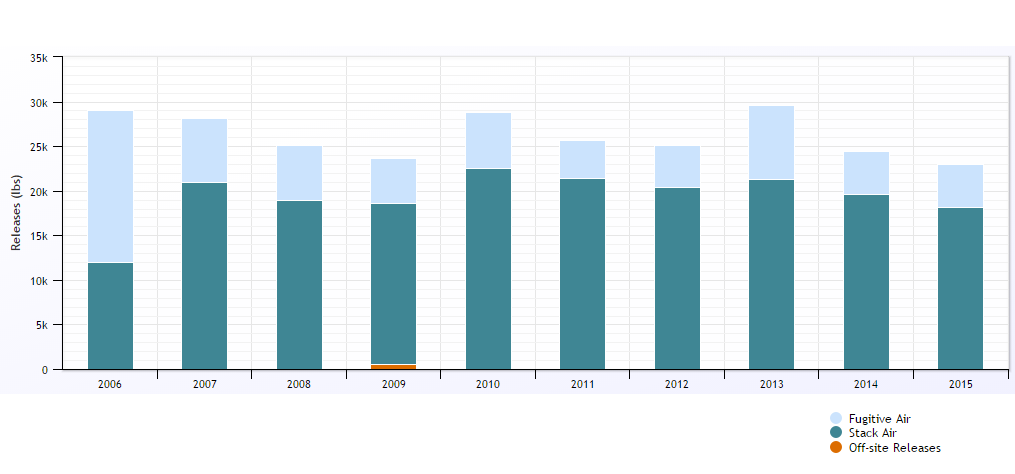

Click the graphs below to view TRI data for Shenango, Clairton, and Monessen. These graphs depict benzene emissions of each facility and are an example of what can be generated using the TRI reporting tools. Coke oven faclities in Allegheny County are responsible for 83.3% of the county’s benzene emissions. Benzene is a large constituent of coke oven gas, usually released from fugitive emissions (leaks) and is a known human carcinogen.

Shenango

Clairton

Monessen

For more information about hazardous air pollutant releases from coke oven facilities around the country, please see our TRI factsheet.